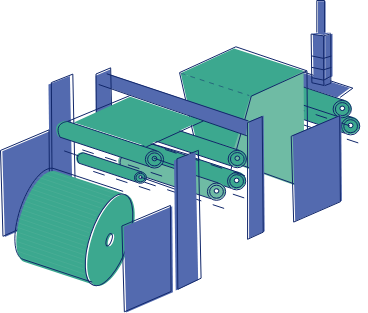

CAST Line

As part of the CAST film production process, melted plastic is poured through a flat head to form a film. An air knife and a vacuum chamber are used to press the film to the chrome surface of a water-cooled roller. Thanks to the very rapid cooling, pouring achieves much higher performance than blow moulding technologies, with greater control over the mechanical parameters of the final film

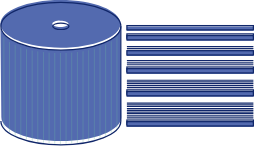

Available types:

- PA/PE

- PA/EVOH/PE

- CPP

Films up to

11 layers

9 extruders

Maximum width of the

final film: 3,250 mm

Film thickness range:

20-300 µm

Maximum capacity:

1,550 kg/h

Maximum machine speed:

350 m/min